HOME > PRODUCTS

The KDS Inc. is built on precision design and

manufacturing for high-speed signal area testing solutions.

IC Tc chamber

Application

- IC contact thermal cycle test

- IC thermal aging analysis

- Quality control and product verification

- Thermal reliability test

Features

- Max 150℃ hot temperature test

- Integrated PC control system

- Safety features

- Data logging and monitoring program

- Compact chamber size and capacity

The Tc chamber helps to test only the temperature of a specific IC on the system board.

With these equipment, it is more efficient to perform a temperature assessment for a specific IC than to test the system board as a whole in a low or high temperature chamber.

IC temperature Tc chamber is a specialized testing equipment designed to evaluate the performance and reliability of Chip under various temperature conditions.

It provides controlled thermal environments to simulate real-world operating conditions and assess the thermal characteristics of IC devices.

The test chamber incorporates precise temperature control mechanisms to create and maintain specific temperature settings.

Also it performs thermal cycling, which involves subjecting the Chips to repetitive temperature changes.

This cyclic testing helps identify potential thermal stress-related issues, such as solder joint fatigue or material degradation, that may affect the reliability and performance of devices over time.

To ensure the safety of the testing process and prevent damage to the device, the chamber may incorporate safety measures such as over-temperature protection, electrical grounding, and insulation.

IC socket

Application

- Semiconductor lot analysis in system board

- Personal computers and workstations

- Servers and data centers

- Gaming systems

- Graphic card

- Embedded systems

- Mobile platforms

Features

- Memory type compatibility

- Customized pin configuration

- 24Gbps speed support

- Support for non-standard board test sockets

- Support both standard and low voltage

- Locking Mechanism

IC sockets in the KDS Inc. provide scalability, compatibility, upgradeability, and ease of maintenance on board systems. These sockets play an important role in facilitating memory module insertion and can maintain the performance of your system and adapt to evolving memory requirements.

IC sockets are designed to support specific memory standards, such as DDR, LPDDR, NAND, etc,.

The IC socket is designed to allow easy removal and replacement of devices while maintaining high speed characteristics. These sockets allow users to identify and replace defective devices without affecting the functionality of other components or the entire system.

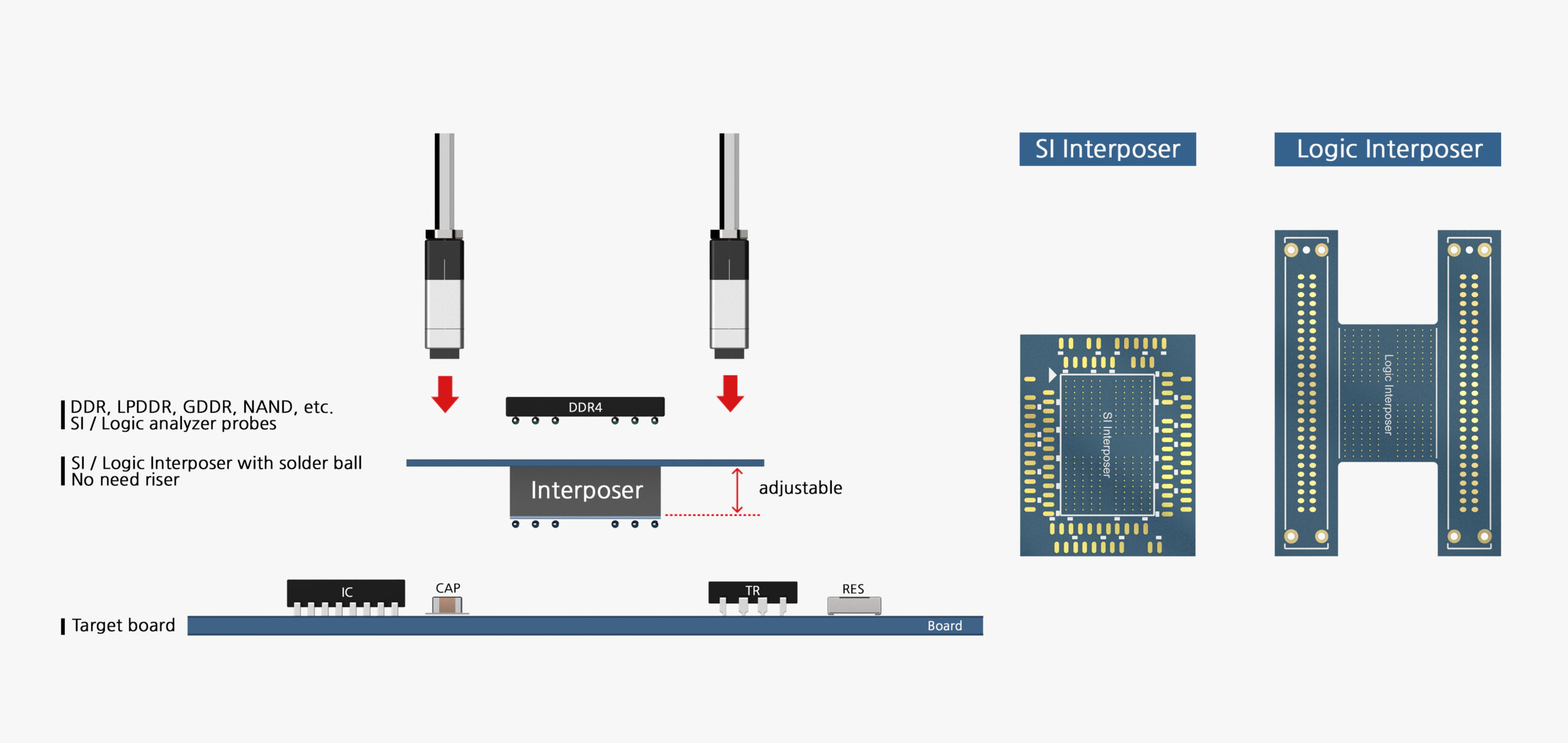

Interposer SI / Logic Probe

Applications

- Signal integrity analysis

- Power integrity analysis

- Logic timing analysis

- DIMM module analysis

Features

- Supports all memory formats (DDR, NAND, LPDDR, GDDR, etc.)

- Supports all DIMM type (UDIMM, SODIMM, RDIMM, LRDIMM, etc.)

- Customized test point

- No need riser Interposers (Customized adjustable step high)

- High speed performance

- Customized to fit specific package

- Support S-parameters for correlation

An interposer is an electronic component or substrate that acts as an intermediary between two other components or technologies, typically serving as a bridge or interface.

Interposers are commonly used in various applications, including semiconductor packaging and high-speed electronic systems.

By using an interposer, it becomes possible to integrate diverse components or technologies that would otherwise be incompatible.

The introduction of an interposer involves carefully designing and manufacturing the interposer to ensure proper electrical connections, signal integrity, and thermal management. The interposer acts as a communication channel, enabling efficient data transfer and ensuring compatibility between the connected components.